The world needs more medical and radioisotopes—and Laurentis answered the call. Laurentis’s innovations resulted in the world’s first isotope production from a working commercial nuclear power reactor.

Inside a groundbreaking technology

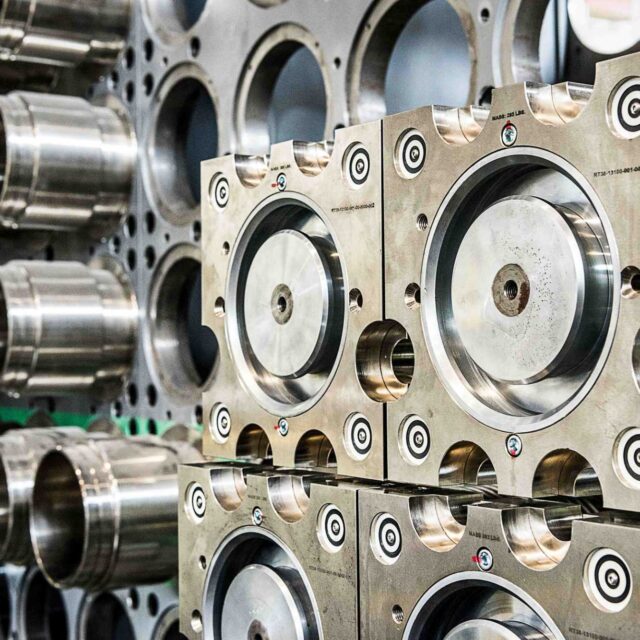

Over a period of several years, Laurentis and BWXT Medical Ltd. worked to develop a proprietary piece of technology that would enable Laurentis to drastically increase both the scale and diversity of its isotope production. The result is the Target Delivery System (TDS).

The TDS is an isotope irradiation system that was specifically engineered to take advantage of the unique design of CANDU reactors. The result is a novel and highly applicable system of isotope production that allows isotopes to be produced and harvested while the nuclear reactor remains online. This means that there is no disruption to the generation of clean energy.

The TDS also represents a significant opportunity for nuclear science to contribute to the well-being of people around the world by offering innovative and alternative approaches to cancer diagnosis and treatment.

Laurentis’s first TDS was installed at OPG’s Darlington nuclear station in Unit 2. It offers a high-volume capacity for irradiating isotopes, as well as high neutron absorption. This results in a higher production yield from the raw material that enters the reactor. Laurentis is currently using the TDS to produce Mo-99 and has plans to use it to produce Y-90. Learn more about these isotopes here.

The TDS has positioned Laurentis as a world leader in nuclear medical isotope production, with the first ever isotope harvest of Mo-99 from a working commercial power reactor, and Laurentis is just getting started. In the coming years, Laurentis will continue to expand its product portfolio and capacity to meet growing global demand for life-saving medical isotopes.

A deeper dive - The TDS in action

The TDS irradiation process begins with a stable isotope. For Laurentis’s Mo-99 production, the target isotope is Mo-98. The target isotope is packed in capsule form with eight capsules housed in a zircaloy magazine. The magazine is lowered into the core of Darlington’s Unit 2 power reactor. High flux neutrons with tremendous thermal power then bombard the target, converting it into Mo-99. After irradiation, the target is lifted out of the reactor, packaged in flasks, and prepared for transportation. The TDS system is fully automated: it lowers new magazines into the core, lifts them out after irradiation, and packages irradiated isotopes into licensed containers for transport.

The system uses four elevators and is controlled using a hybrid of elevators and pneumatics.

Total capacity of the TDS at Darlington Unit 2 can satisfy a significant portion of global demand for Mo-99.