Through its subsidiary, Canadian Nuclear Partners, Laurentis is supporting the refurbishment of Societatea Nationala Nuclearelectrica’s Cernavoda nuclear station in Romania and helping with the commissioning of a tritium removal facility currently under construction.

Supporting refurbishment and detritiation

Societatea Nationala Nuclearelectrica (SNN) is a state-owned power utility, reporting to Romania’s Ministry of Energy. It operates Cernavoda Nuclear Power Plant, a two-unit CANDU 6 station at Cernavoda. The Cernavoda station generates about 18 per cent of Romania’s electricity. Cernavoda Unit 1 (C1) came into service in 1996, while Cernavoda Unit 2 (C2) came online in 2007.

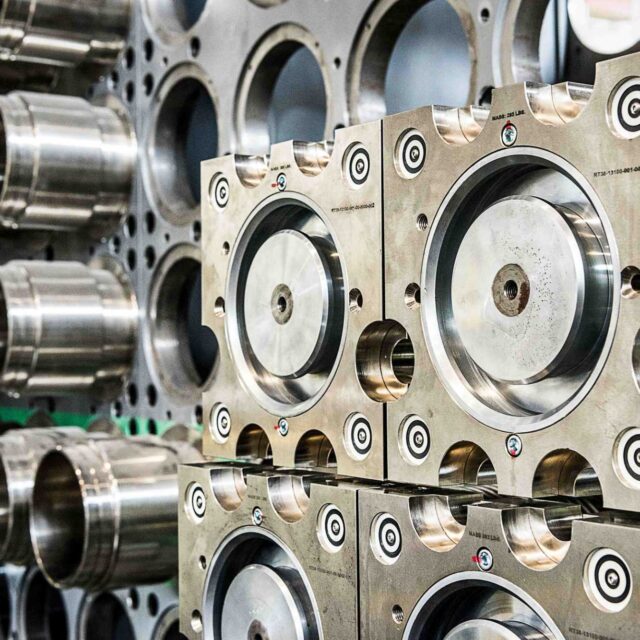

Laurentis subsidiary Canadian Nuclear Partners is supporting SNN through planned refurbishment activities. During a refurbishment outage, some systems and components at Cernavoda that are not subject to refurbishment activities will still require careful planning to avoid degradation and to maintain them in a safe state for the duration of the plant’s stoppage. Laurentis has developed a program to protect the integrity of SNN’s Unit 1 reactor while it is drained of water during refurbishment. This includes a subcontract to Framatome, in Germany, to use its proprietary Film Forming Amine (FFA) technology. FAA has been deployed in the Darlington Refurbishment to conserve and protect water-steam systems while dry, reducing or preventing the need for maintenance.

Work by Laurentis on the Cernavoda refurbishment will occur in two stages. Phase one, system analysis and design engineering, occurred over 21 months in 2021 and 2022. Phase two, implementation, is scheduled to move forward in 2026-27, following regulatory approval for SNN’s refurbishment.

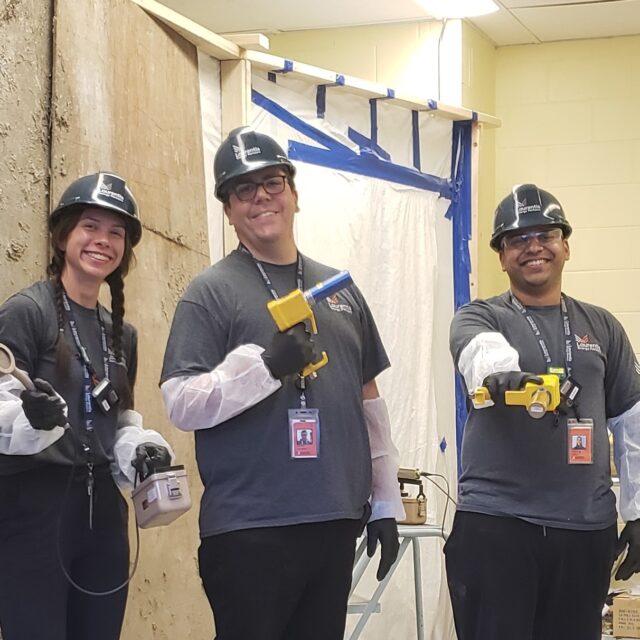

The contract also includes a Darlington Training and Mentoring Program for Cernavoda personnel who will be involved in the implementation of the C1 refurbishment. This program will establish clear and well understood standards for the owner’s role in ensuring safe, quality, on-time and on-budget delivery of the refurbishment program, it will provide a solid foundation for the scope of work and methods that OPG uses to manage a refurbishment project and it will enhance the ability of project personnel to identify, analyze, and solve management problems encountered over the course of the project. Three cohorts of Cernavoda staff are participating in 10-week sessions at the Darlington training centre.

Furthermore, Laurentis is leveraging its significant experience in the commissioning and operation of its own detritiation facilities at Darlington to help SNN build a detritiation facility at Cernavoda. As a subcontractor to Kinetrics, which is acting as Owner’s Engineer for the construction of the project, Laurentis will make an important contribution in the key phase of commissioning of the tritium removal facility.