As experienced nuclear industry leaders, Laurentis has completed various maintenance and inspections-related projects to keep nuclear plants running safely and at optimal efficiency for the entirety of their operating life.

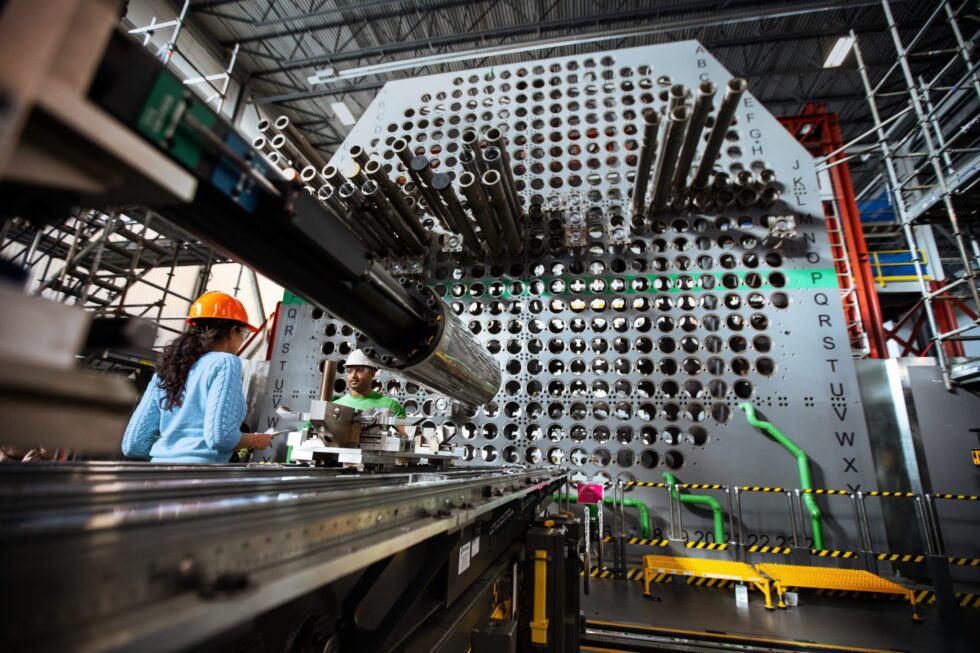

The importance of SLAR campaigns

Laurentis has successfully completed numerous Spacer Location and Repositioning (SLAR) campaigns. Outside of the on-channel inspection, Laurentis also maintains, calibrates, tests, and commissions all SLAR equipment to make sure it is ready to use.

SLAR campaign equipment includes the SLAR and Modal Detection and Reposition (MODAR), which detects and repositions garter springs in a wet, de-fueled channel. This ensures adequate separation between calandria and pressure tubes.

As nuclear plants around the world continue to age, SLAR campaigns are a vital expertise in keeping these reliable, low-carbon energy sources operating as safely and efficiently as possible.

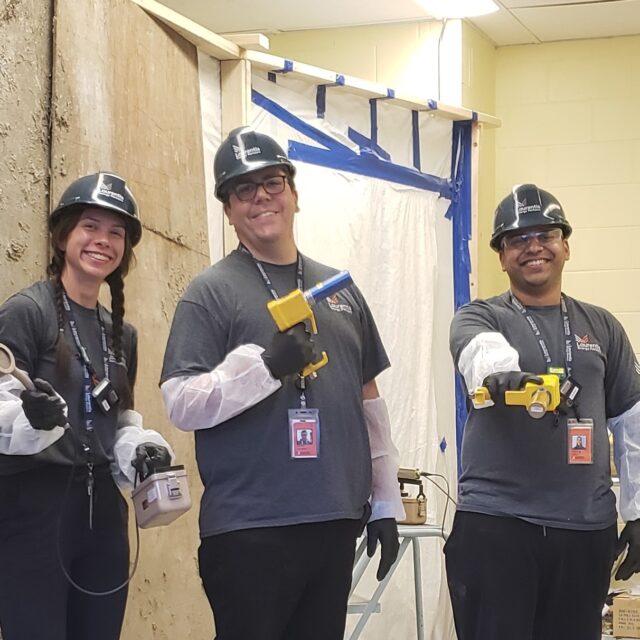

Nuclear reactor maintenance

Laurentis’s advanced tooling and expert crews are trusted to perform critical and routine maintenance on operating nuclear reactors.

Aerial inspections

Aerial inspections with remotely piloted aircraft systems operated by Compliant Operator Special Flight Operations Certificate crews as designated by Transport Canada.

CIGAR inspections

Laurentis’s Channel Inspection and Gauging Apparatus for Reactors offers a fully automated, remotely operated inspection system designed to perform multi-channel, multi-task inspection of CANDU reactor fuel channels.

Balance of plant inspections

Balance of plant inspections and services to keep your entire operation meeting the highest safety standards and running at peak performance.

Inspection of nuclear fuel channels

Volumetric and dimensional inspections of nuclear fuel channels include a review of the fuel channel lifecycle management plans and detailed recommendations to maximum optimization. This inspection includes engineering, radiation protection, and operations support.

Keeping reactors efficient and online

Other maintenance and inspection services and capabilities that Laurentis specializes in and projects delivered, including in partnership with OPG’s Advanced Inspections and Maintenance team (AIM):

- Scanning Tool for Elongation Measurements

- Fret Replica Inspection Laser System analysis

- Training and expertise/execution for Balance of Rotating Equipment

- Training, expertise/execution and tooling for Horizontal Flux Detector install and removal

- Single fuel channel replacement (SFCR) training and expertise/execution for mock-up and flask rentals, including active component transfer system (ACTS)

- Data acquisition power rundown monitoring equipment, expertise, training, and equipment

- Assessments (order completion, whether it be backlog, outage, preventative maintenance)

- Radiation protection field team services

- Vacuum building outages support using Remotely Piloted Aircraft System (RPAS) or drones

- RPAS and drones for renewable generation (hydro, dam inspections, head gate integrity)

- Heavy Water Transfer Facility at NB Power, reducing rates of coolant and moderator water (tritium removal)

- Steam generator support and expertise

- Used fuel container programs for Small Modular Reactors (SMRs)

- Monitoring, diagnostics, and preventative maintenance