Accent: opa693jt45ve

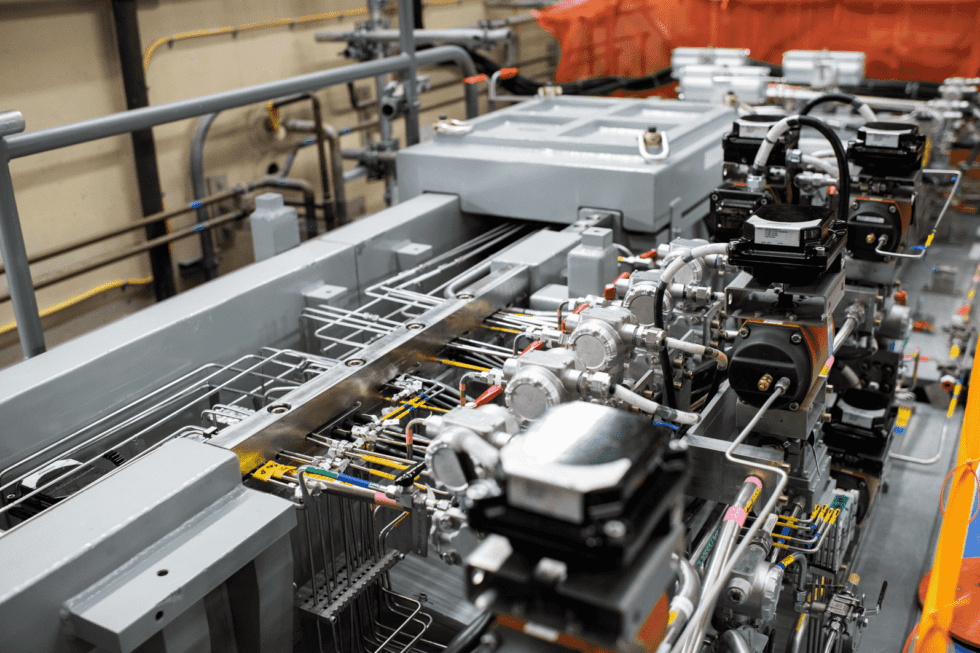

Welcome to Laurentis Energy Partners, a company dedicated to excellence in every aspect of nuclear energy and the industries it supports. With its in-depth knowledge of the nuclear sector and a talented, experienced team, Laurentis is your partner in advancing and sustaining your nuclear ambitions for a cleaner and healthier tomorrow.

Laurentis has quickly established itself as a leader in every aspect of the nuclear industry. From SMRs to isotopes to inspections, maintenance, and refurbishment, this company is a go-to partner for those looking to harness the incredible power of nuclear energy.Aida CipollaDirector, Laurentis Board of Directors